Optical Chemical Sensing

Optical Chemical Sensing is used across a wide range of applications, from testing the safety of drinking water to monitoring blood glucose levels. It can even be used to check the quality of your whisky!

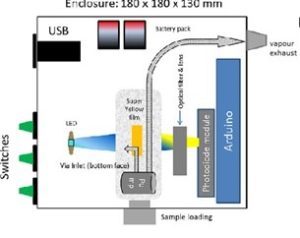

The University uses conjugated polymers; thin, flexible, electrically conductive, plastic like materials, as optical chemical sensors that can be made into thin films. Thin film sensors have advantages over other analytical devices since they can be comparatively inexpensive, easily-processed, fast responding and are highly-sensitive. Data from film sensors can be analysed and monitored with ‘off-the-shelf’ photonic devices like light emitting diodes ‘LEDs’ and photodiodes.

Similar materials are found in some commercial T.V.s and mobile phones. They form a major component of the Group’s work on organic solar cells, LEDs, lasers and studies into the effects and properties of light (photophysical studies).

Optical Chemical Sensing is being studied at the University for it’s potential in detecting explosives. This may allow for increased effectiveness when detecting Improvised Explosive Devices (IEDs) and has humanitarian applications.

Conjugated polymers allow electrons to move freely along their long chains causing them to emit light. If an electron-deficient compound, like the explosive TNT, touches the polymer, the energy is transferred from the polymer to the explosive and the light emission is lost. By monitoring this loss of light, it is possible to assess the presence of explosives across an area like a minefield.

By understanding the characteristics of conjugated polymers, the Group have been active in developing portable devices to detect explosives in the field, new types of coatings for sensor specificity, preconcentration methods for trace explosive sampling, pesticide sensing and even the use of honeybees in landmine detection.